Casebeskrivelse:

Grundfos is a pump manufacturer, based in Denmark, with more than 18,000 employees globally. The annual production of more than 16 million pump units, covering circular pumps, submersible pumps and centrifugal pumps. Grundfos also produces electric motors for the pumps as well as electric motors for separate merchandising. Grundfos develops and sells electronics for controls for pumps and other systems.

Grundfos is a pump manufacturer, based in Denmark, with more than 18,000 employees globally. The annual production of more than 16 million pump units, covering circular pumps, submersible pumps and centrifugal pumps. Grundfos also produces electric motors for the pumps as well as electric motors for separate merchandising. Grundfos develops and sells electronics for controls for pumps and other systems.

Since its foundation Grundfos always has tried to be one step ahead of time. In times of resource scarcity and mass pollution Grundfos tries to make a difference. To improve its green reputation and develop its green stamp, a team was created which is focusing only on the implementation of measures to fight against resource and pollution challenges. The first task to start with is the establishment of a working circular economy.

Circular Economy

Our current model of production is reaching its physical limits. With easy access to cheap raw materials and energy, it is possible to produce a wide range of products without worrying if these will be available in the future. The main concern about this linear models is that resources are limited and this limit will be reached sooner or later. Thus, some companies are engaging in a new wave of green approach to the way they use their resources. Mostly by trying to reuse or recycle its products and putting them back in the manufacturing process. Some important steps are necessary to achieve circular economy inside a corporation: Circular Economy Design, New Business Models, and Reverse Cycles and Enablers/Cooperations.

Circular Economy Design

In order to put used products back in the manufacturing loop, its design must be optimised. This way, companies are more willing to implement the Circular Economy into their structures by minimizing recycling or reusing costs.

The best way to implement this is by using easier to recycle materials, standardised components, design-for-manufacturing criteria and modular designs.

New Business Models

The new opportunities created by implementing a Circular Economy must be seized by implementing new business models that contemplate the upcoming used materials. By reusing parts of even full products, new uses could be found and even create a whole new business branch. This could be by creating a new company partition that would manage the new brand branch.

Reverse Cycles and Cooperations

To further cement the economics of the circular design, the reverse cycle’s processes must be optimized. Both by further improving workers’ skills regarding reuse of materials as well as in terms of infrastructure. More cost-effective and quality collection and treatment systems, warehousing and reassembly will all contribute towards a very effective circular model. Cooperations with other businesses also play an important role since, most of the times, companies do not have a complete control over their supply-chain.

The Challenge

This initiative is pointed towards resolving the following question-problem:

How can Grundfos better reintroduce their waste materials and components into a more eco friendly, sustainable and value-generating cycle?

The challenge presented to solve revolves around the difficulty or associated costs of recycling and/or reusing pump components, as well as the reintegration of end-of-cycle pumps and components into the circular economy cycle which allows them to be repurposed, as opposed to being discarded, resulting in loss of their residual value and in environmental consequences.

The solution to this problem is expected to be a creative process and/or product innovation, which draws from the learning environment and multi disciplinarity of the project and the people involved in it, in order to provide not only significant relief to the drawbacks of not running a business with circular principles and product lifecycle stage value extracting, but also as a springboard for getting the most out of the product for the sake of minimising environmental impact, as well as maximising value for the company and all the stakeholders in the process.

Team Members

• Trine Hald Holmsgaard (Industrial Design)

• Karina Roejkjaer (Industrial Design)

• Francisco Almendra (Entrepreneurial Engineering)

• Thien Quang Tran (Industrial Design)

• Jesper Soerensen (Industrial Design)

• Adrian Gangkofer (Entrepreneurial Engineering)

Konceptvideo:

Concept

Tracking Return System

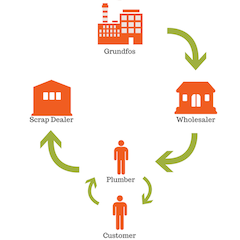

Upon further researching, it was clear that such businesses as Grundfos lose track of their products after these leave the factory. Because Grundfos sells pumps to wholesalers that then sell to plumbers, it is complicated to keep track of such pumps. This also creates some difficulties of bringing them back since the installation and uninstallation is done by a 3rd party – the plumbers. We will discuss the importance of this stakeholder in the next chapter.

Moreover, it was also noted that there was not a concrete number on the amount or the type of pumps that are being returned as the 7000 figure was an approximation. Thus, the Tracking Return System was designed to, not only increase the amount of pumps being returned, but also to keep track of the pump’s use, the type, installation date and uninstallation date. A more precise description of the system will be presented in a later chapter, but first, the involved Stakeholders or Intervenients had to be identified.

Supply Chain / Stakeholders

To find a gap for process improvement and circular economy implementation, the supply chain was thoroughly analysed and its key stakeholders identified as such:

•Grundfos

•Plumbing retailers

•Scrap dealers

•Plumbers

•Customers

Current supply chain model

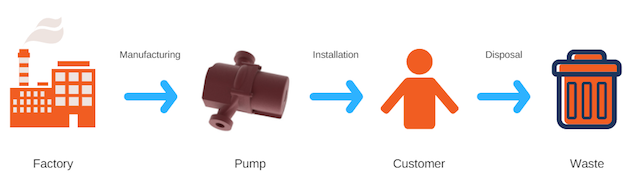

Today, the value chain of a pump’s life is rather linear, starting in its production and manufacturing, going through use and then disposal:

This model, although straightforward and commonplace in most production companies, has the enormous drawback of not applying their residual end products into something valuable, which forfeits a sizeable amount of the product’s possible value. Additionally, such value is also sorely missed among the very intervenients in the supply chain, who would greatly benefit from additional streams of revenue or the opportunity to provide a better and greener service. This will be addressed in the ensuing section.

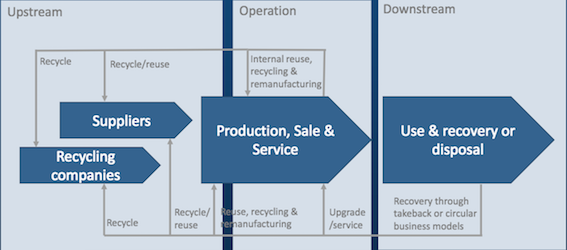

Desired supply chain model

As the aim of the project is to find a process which not only extracts as much possible value as possible from each step in the value chain, but that also generates less waste and involves less polluting subprocesses than those embodied in remanufacturing or, ironically, recycling. This can be achieved through a circular value chain and, eventually, a circular business model:

This system allows for value extraction at each step of the process and, most importantly, facilitates the return of the end products to the original producer so that they can make the most out of it, as opposed to discarding it. This brings additional value to each part of the supply chain, yet for it to be provided, there must be an enforcement system in place so that the key stakeholders will be willing to take a stake at this new and sometimes hard to grasp business model. And to do so, stakeholders will be identified and incentive/reward systems will be presented.

The System

The complete system is made of 2 parts: the app and the tracking system. The app the Plumbers use to input the data about the pump and to get their reward – this aims to increase the amount of returns by engaging the key stakeholder, the plumbers. And the tracking system which fulfill the current data that Grundfos has about the pumps.

App

The app is to be downloaded and used by the plumbers and works together with a QR code in the Pump and a QR code in the container placed at the scrap dealer.

Upon installation, the plumber scans the QR code and the app creates a data sheet for the pump. This data sheet is filled automatically with the installation date, the purpose of the pump, and the location. This is the main way of obtaining new and invaluable data on the pumps that can be further used by Grundfos. This action by the plumber rewards him/her throughout a Reward System that can be claimed at partners’ locations. By placing containers at key disposing locations, Grundfos facilitates the old pumps’ gathering. As the plumber approaches such containers, he/she places the old pumps inside, scans the QR code in the container and is instantly rewarded by engaging in the return system.

Reusing

Pros of reusing vs recycling

This is an effective way of incentivising the return of old pumps by the plumbers.

In a circular economy, every cost has to be taken in consideration. Specially the returning and transforming process, everything should be as simple and cheap has possible. This way, companies such has Grundfos are more likely to adopt this new approach to business.

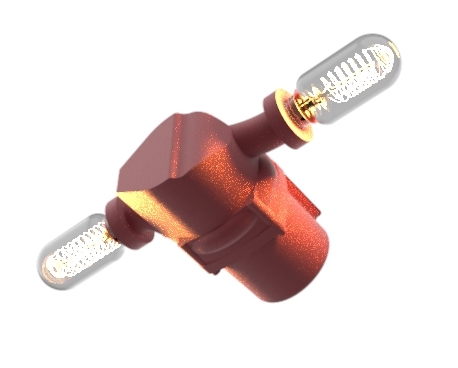

So, when considering recycling or reusing materials or whole parts, the one that allows the company to do minimal transformation to the used materials is the best. That is why the group opted to reuse the old pump housing, simply but giving it a new purpose. The rest of the materials such as copper and aluminium will be recycled as Grundfos are doing it now

Reuse for design

The old look and condition of used pumps is a problem when trying to recycle its materials. Many things might happen to a pump during its life-cycle that will impact how or what can be reused. Also, as part of the reusing process, it is important to add value to the product.

To handle all these considerations, a new purpose that both adds value to the used Grundfos pumps and requires little to no transformation was key – the interior design idea was born.

The retro interior design is a trend to consider and old pump housings will fit in it perfectly. More precisely, these housings can be used as table or ceiling lamps

Videoskitser:

Sketch 1

Designprocess:

Fieldwork

One of the first steps in this project was gaining knowledge about the background for the project. The field trip to Grundfos and Skive City Hall was the first step in understanding more about circular economy and the problems and difficulties implementing it. Furthermore some of the specific problems Grundfos was facing were introduced. From those who concerned us, it was notable that the number of returned pumps pointed towards a very small scaled and primitive operation (roughly 7000 pumps pr. year), which is too small to be a concern. So it was clear that one of the project’s directions would be to increase Grundfos’ returned pump intake.

The visit to Skive City Hall gave insights to different projects working with recycling. For example the reuse of old building materials.

Process

After receiving the the pump from Grundfos in the group, the first thing that was done was a brainstorm. This created a lot of ideas as to how the given problem could be solved. The brainstorm helped getting the mindset on the assignment and worked as a kickoff to the project.

To sum up and discuss the observations made at Grundfos and at Skive CityHall, the Elito method was implemented. This method made it possible to gain a quick overview of the most important observations, trying to understand the logic behind each of them and afterwards, making it possible to generate ideas, from the observations.

After a discussion of each idea, three concepts were selected: using the pump for a generator to rain water, improving the return system and adding a tracking system, and making industrial furniture from the pump housing. To get a viable answer as to whether the ideas could be implemented, users were consulted and observations concerning the market of interior design, were made. This helped getting new insights to the ideas. Here it became clear, that the concept regarding the generator were a tad too extensive and comprehensive to work with. Therefore the primary focus moved to the return/tracking system and the interior design.

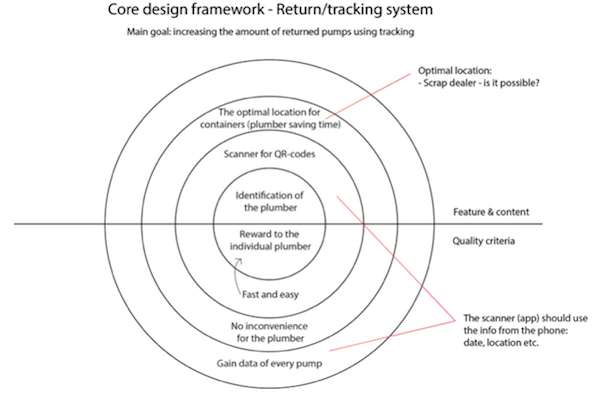

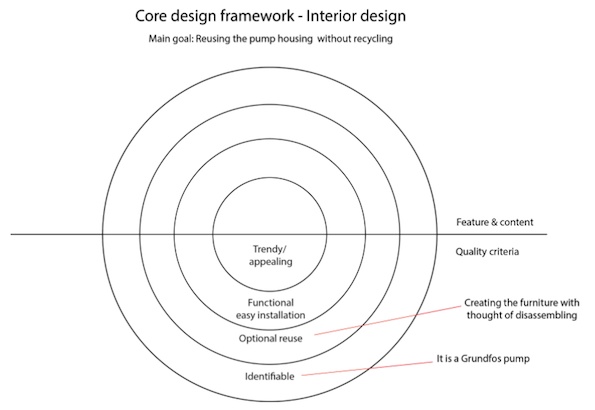

Core Design Framework

The core design framework was used on the primary ideas. This helped identifying the primary quality criteria and the essence of the ideas.

The core design framework for the return/tracking system is based on a call with a plumber and his experience. He was focused on not using extra time and would rather have ten more minutes for his break, than writing the serial number in order to register the products. The used pumps he would collect and bring to a scrap yard.

The core design framework for the interior design is primary focused on the quality criterias and not the features and content. This decision were made because different furnitures need different features and content.

Meeting with Grundfos and the following process

At the case partner meeting with Alexandru, the three ideas were presented (generator, return/tracking system, interior design). The feedback was to try and combine the two primary ideas. By doing that the whole life of a pump would be shown and therefore this solution made sense.

The generator idea he found interesting but he could also see the complications with the structure of the specific pump.

Overall he seemed satisfied with the amount of work that was put into the project.

The primary focus after the meeting was to contact a scrap dealer, whether or not it would be possible for Grundfos to put a container at the scrap yard for the pumps. The idea with a container, at the scrap yard originated from the thought of not making the return an extra burden for the plumber. By putting the container at a place where the plumber would go anyway this would be prevented.

After talking to a scrap dealer it became clear that they also were focusing on new ways to improve circular economy. Therefore, they were interested in the idea of helping Grundfos by having a container for water pumps, at the scrap yard. With this clear the development of the final concept began.